Project Background

In the traditional process of measuring the volume of mining truck sand material, there is a high level of manual involvement, and the measurement efficiency is relatively slow. Additionally, the calculation models cannot accurately represent the actual shape of the sand pile, leading to errors in manual measurements. Moreover, the level of measurement automation is relatively low, as it requires experienced personnel to select representative positions for measurement. LiGrip H300 can automatically conduct measurements without manual intervention, quickly obtaining a large amount of accurate point cloud data. Furthermore, the LiDAR360 software automates data analysis, providing an efficient, accurate, and automated solution for volume measurement.

Technology Process

Data Collection

LiGrip H300 is a handheld SLAM (Simultaneous Localization and Mapping) 3D laser scanner developed by GreenValley. It is equipped with various sensors, allowing for the rapid capture of large-scale scene data. It supports multiple platforms and modes of operation such as backpack, vehicle, and UAV kit. LiGrip H300 supports multiple high-precision mapping methods, including PPK-SLAM, RTK-SLAM, and SLAM, enabling quick acquisition of point cloud data with absolute coordinates. It features a panoramic camera and utilizes 32-line point cloud scanning technology, offering improved lighting effects and a scanning frequency of up to 640,000 points per second. The device can achieve a maximum absolute accuracy of 5 centimeters.

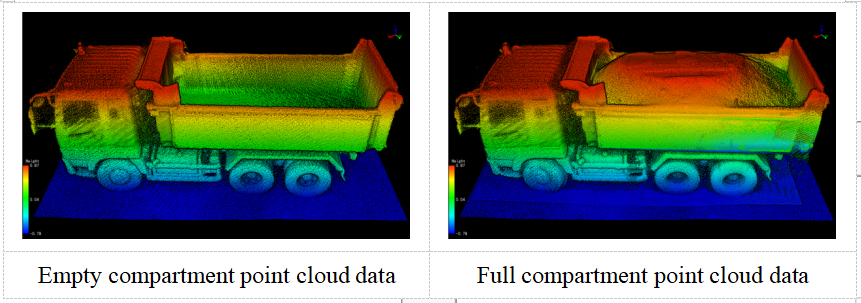

Empty compartment measurement: Measurement personnel use the LiGrip H300 handheld laser scanner to measure the empty compartment of the vehicle. The collected point cloud data covers the entire vehicle, obtaining the empty compartment model and the actual capacity of the transport vehicle.

Full compartment measurement: After the vehicle is fully loaded, the LiGrip H300 handheld laser scanner is used again for a full scan of the compartment, using the same method as above.

In practical applications, it is also possible to reverse the order of the two processes according to the requirements, first measuring the full compartment data and then measuring the empty compartment data after unloading.

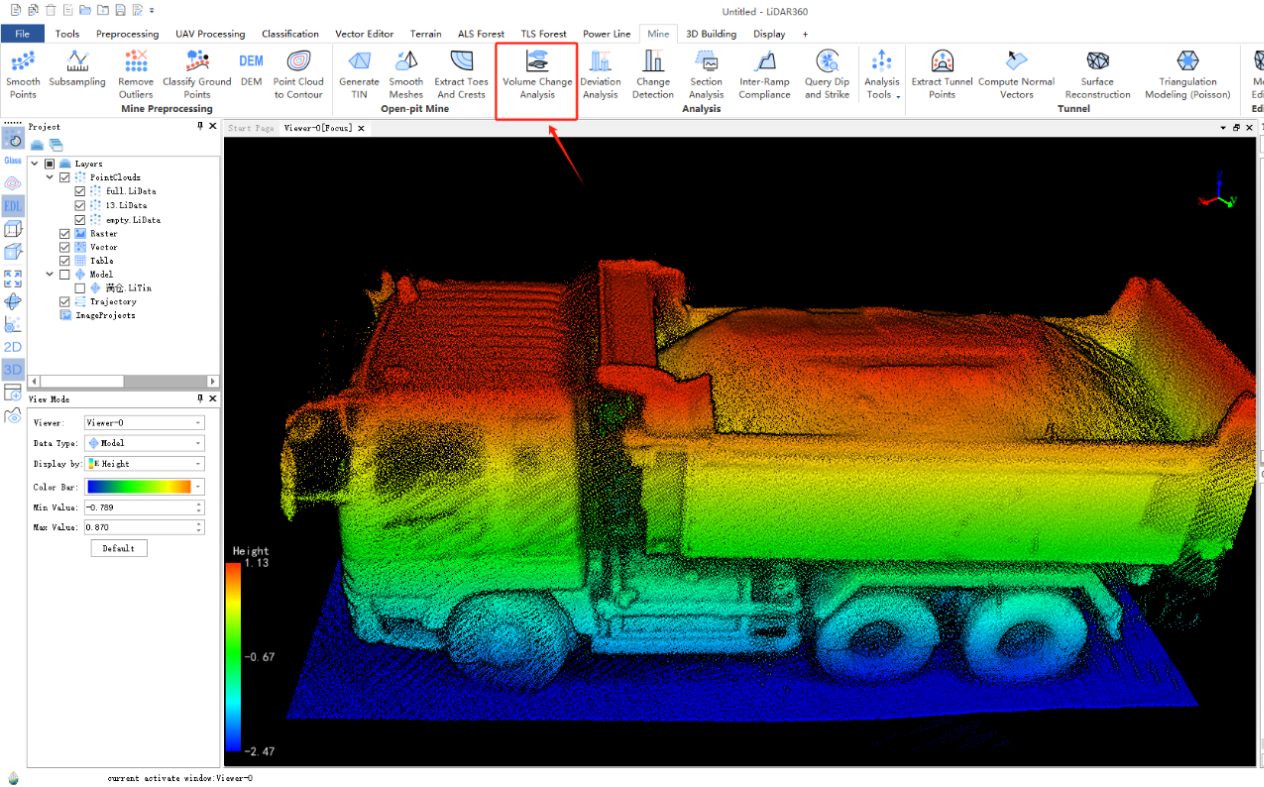

Volumetric Calculation

LiDAR360 is a laser radar point cloud data processing and analysis software developed by Digital Green Earth. It features over 10 advanced point cloud data processing algorithms and can handle more than 300GB of point cloud data simultaneously. The platform includes a range of vector editing tools and automatic point cloud classification capabilities.

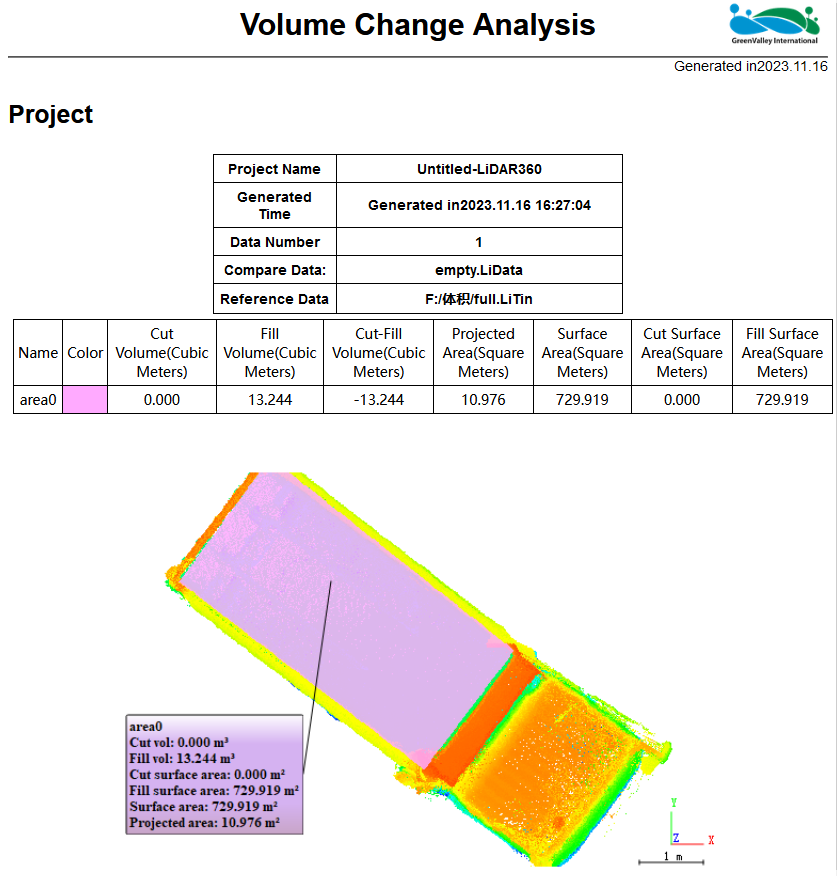

The volume change analysis function in LiDAR360 allows for the calculation of fill and cut volumes based on two sets of point cloud data using a model or a plane as reference. It generates reports showing the calculated volumes. According to this feature, the sand transported by the vehicle amounts to 13.244m³.

Accuracy Verification

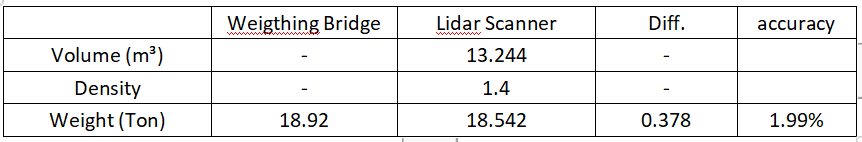

In order to further verify the accuracy and feasibility of laser measurement, the sand material was weighed through the measurement system and the accuracy of the calculation results was verified.

①The weighing system measured the weight of the sand material as 18.92 tons.

②Knowing that the density of the sand material is 1.4 tons/m³, and using laser measurement, the volume of the sand material was determined to be 13.244m³. This allows for the calculation of the weight of the sand material to be 18.542 tons.

③Comparing the calculated result with the weight obtained from weighing, an error of 1.99% is observed. This indicates the feasibility and high accuracy of this approach in practical applications.

Conclusion

GreenValley provides a convenient and comprehensive solution for volume measurement. By combining LiGrip H300 with LiDAR360, the process of measuring the volume of mining truck sand material becomes digitized and intelligent, addressing issues such as high labor costs, low measurement efficiency, and inadequate accuracy in traditional methods. This solution offers a more reliable and efficient approach for related industries. In the future, with continuous technological advancements, laser radar technology and related software analysis tools will continue to play a greater role, bringing more innovation and convenience.