Traditional Stockpile Measurement Challenges:

Time-Consuming, Labor-Intensive, and Inaccurate

In ports, waterways, and sand mining sites, measuring the volume of sand stockpiles or sand carriers is a routine yet frustrating task. Traditional methods rely either on manual tape measurements—literally climbing sand piles—or on total stations with multiple point surveys. A single measurement often takes three to four people half a day, and the results are easily affected by weather, terrain, and human error, leading to unstable accuracy. Even worse, loose edges of sand piles can collapse, creating serious safety risks for personnel.

Is there a solution that is fast, accurate, and safe?

The answer is LiDAR.

LiDAR: A “CT Scan” for Sand Piles

LiDAR (Light Detection and Ranging) works like a 3D CT scan for sand piles. By emitting laser pulses and capturing hundreds of thousands of spatial points per second, LiDAR rapidly generates high-density 3D point cloud models. Whether using a handheld device to walk around the site or a UAV flying at low altitude, the complete shape of a stockpile can be captured within minutes.

In a provincial-level salt stockpile inventory project, results showed that a dual-LiDAR system achieved a volume measurement error of less than 1%, with efficiency improved by more than 10× compared to traditional methods.

Three Game-Changing Advantages That Solve Industry Pain Points

1. Non-Contact Measurement for Enhanced Safety

Surveyors no longer need to climb steep or unstable piles. With handheld devices, measurements can be completed while walking on flat ground. In one port sand-ship application, measurement time was reduced from 4 hours to 30 minutes, with zero safety incidents.

2. High Precision and Automation for Maximum Efficiency

Take GreenValley Intl’s LiGrip O2 as an example. This handheld SLAM LiDAR scanner emits up to 640,000 points per second, with an absolute accuracy of 3 cm. The device automatically stitches point clouds and generates 3D models. Combined with LiDAR360MLS software, volume can be calculated with one click—eliminating manual drafting and rough estimation.

3. All-Scenario Adaptability with High Mobility

From narrow ship holds to open stockyards and irregular natural sand piles, LiDAR offers flexible solutions:

● Handheld SLAM LiDAR: Ideal for small to medium stockpiles, scan while walking

● UAV-mounted LiDAR: Suitable for large-scale open areas such as mines

Workflow

Step 1: On-Site Planning

Plan the scanning route based on site conditions. Ensure a 3–5 m overlap between the start and end points to guarantee complete data coverage.

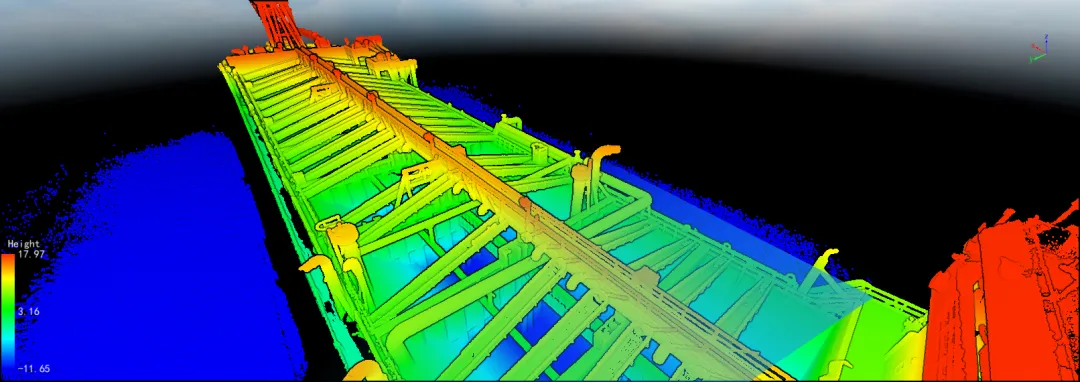

Step 2: Empty-Hold Data Collection

Operators carry the LiGrip O2 and walk once along the ship’s side. The LiDAR rotates 360°, capturing 3D coordinates and imagery simultaneously to fully cover the entire ship hold.

Step 3: Full-Load Data Collection

Scan the fully loaded ship using the same method.

Step 4: Point Cloud Processing

Import the data into LiDAR360MLS software for automatic SLAM processing and filtering, generating point clouds for both empty and full conditions.

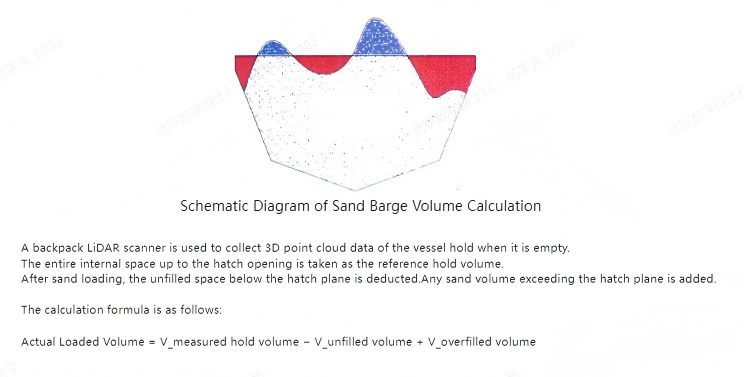

Step 5: Volume Calculation

Calculate:

● Fill volume of the empty hold (actual hold capacity)

● Fill and cut volumes of the full hold

In the full-load model, the red area represents unfilled volume below the hatch level, while the blue area represents the excavated (loaded) volume above it.

Using the specified formula, the final sand ship stockpile volume is obtained.

One-Time Investment, Long-Term Returns

Although LiDAR scanner requires a higher initial investment, the overall cost is far lower than traditional methods in the long run. One aggregate yard calculated that with 50 measurements per year, traditional surveying required a two-person team plus a total station, costing over $21,000 per year. After switching to handheld LiDAR, a single operator could complete the task, reducing annual costs to under $4,200, with a return on investment in just 8 months.

More importantly, accurate data improves inventory management and reduces trade disputes. One building materials group reduced inventory discrepancies from ±5% to ±1%, avoiding economic losses of over $280,000 per year caused by inaccurate data.

Sand ship stockpile measurement may seem like a small task, but it is a critical component of smart logistics and digital twin ports. LiDAR not only changes how measurements are taken—it upgrades traditional experience into precise digital assets. Port operations, resource scheduling, and trade settlement are all entering a new era of digitalization.